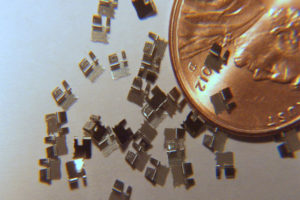

Contact springs are manufactured utilizing OMNI Engineering, Inc.’s advanced micro miniature metal stamping capabilities. The customer’s original design required the use of multiple wire welded components. By utilizing our design and tooling capabilities we were able to lower cost, increase productivity, and improve quality with a one piece component. The contact spring is a component for use in trimming potentiometers. Several variations are manufactured: contact springs are stamped from 302 stainless steel and/or C7700 nickel sliver alloy. Other variations are stamped using C17410 beryllium copper / paliney 6 inlaid material. The parts are stamped using 2 up carbide progressive dies in high speed Bruderer presses. We currently stamp more than 100 million parts annually, holding dimensional tolerances of +/-0.0005, and angular tolerances of +/-1/2 degree. Quality is verified through dimensional, gram force, camber, and visual inspections. Real time SPC data is collected during manufacturing and data is supplied with each shipment.

To learn more about this project, or the processes used to manufacture it, see the table below or contact us directly.